A buzzing industrial facility, a complex network of wires, and a sudden, inexplicable shutdown. You're called in, armed with your toolkit and experience, but before you touch a single wire, you need to speak the system's language. That language, the visual shorthand that underpins every motor control system, is precisely what Common Power & Motor Control System Symbols are all about. Mastering them isn't just about reading a diagram; it's about diagnosing issues faster, ensuring accurate wiring, and keeping operations — and people — safe. It's the difference between fumbling in the dark and illuminating the entire circuit with a single glance.

At a Glance: Decoding Electrical Schematics

- Universal Language: Power and motor control symbols provide a standardized visual vocabulary for electrical systems, understood across the industry.

- Essential for Pros: Crucial for US electricians to interpret schematics, troubleshoot malfunctions, and perform accurate maintenance on industrial automation.

- Categorized for Clarity: Symbols are typically grouped by function: power sources, control devices, motors, protective elements, and conductors.

- NEC Compliant: The National Electrical Code (NEC) provides the framework and guidance for understanding and implementing these symbols in real-world applications.

- Practice Makes Perfect: Regular exposure and active interpretation of schematics are the fastest routes to fluency.

The Silent Language of Power: Why Symbols Rule the Shop Floor

Imagine trying to navigate a bustling city without road signs or traffic lights. Pure chaos, right? Now, picture a modern industrial facility: an intricate dance of power, logic, and motion, all orchestrated by sophisticated motor control systems. Without a standardized language to represent every wire, switch, and motor, these systems would be impossible to build, maintain, or troubleshoot efficiently. This is where common power and motor control system symbols become indispensable.

For electricians working with industrial automation in the US, these symbols are more than just squiggles on a page; they're the blueprint, the diagnostic tool, and the safety manual all rolled into one. They allow you to quickly grasp a system's intended operation, identify potential failure points, and communicate effectively with other technicians, engineers, and installers. This standardized visual language, often guided by NEC safety standards, minimizes errors, boosts efficiency, and significantly enhances electrical safety in the workplace across the board.

Your Field Guide to Control System Categories

To make sense of the vast array of symbols, we typically categorize them by their function within a power or control circuit. Think of these categories as chapters in a comprehensive technical manual, each describing a different type of component and its role. Understanding these groupings is your first step toward quickly locating and interpreting specific elements on any schematic.

1. Power Sources: The System's Energy Core

Every electrical system needs power. These symbols show you where that energy originates, whether it's alternating current (AC) from the grid or direct current (DC) from a battery or rectifier. They dictate the voltage, phase, and overall electrical characteristics feeding the circuit.

2. Control Devices: The System's Hands and Eyes

These are the components that allow human interaction or automated responses within the system. They send signals, detect conditions, and initiate actions. Think pushbuttons, selector switches, and limit switches that sense position or presence.

3. Motor Starters: Igniting the Rotational Force

Motors don't just magically turn on. They often require specialized devices to handle the high inrush currents during startup, protect against overloads, and provide a means of control. Motor starters, typically comprising contactors and overload relays, are the bridges between the control logic and the motor's power requirements.

4. Motors: The Workhorses of Industry

Without motors, industrial automation wouldn't exist as we know it. These symbols identify the type of motor—AC or DC—and often provide clues about its phase configuration or special characteristics. They represent the ultimate output of many control systems: converting electrical energy into mechanical motion.

5. Protective Devices: The System's Guardian Angels

Safety and system integrity are paramount. Protective devices are designed to automatically interrupt circuits under fault conditions like overcurrents, short circuits, or ground faults. Fuses, circuit breakers, and ground fault interrupters fall into this critical category.

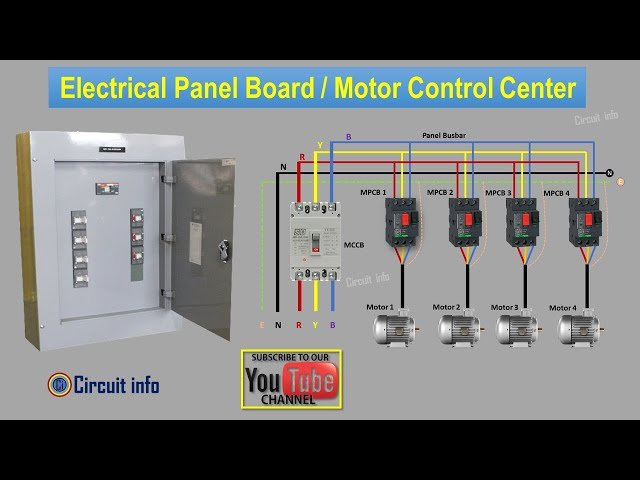

6. Conductors: The System's Arteries

These symbols represent the pathways for electrical current – the wires, cables, and busbars that connect all the components. Understanding how conductors are drawn (connected, crossed without connection) is fundamental to tracing current flow.

Decoding the Blueprint: Specific Power & Motor Control Symbols Explained

Now, let's get down to the brass tacks: the actual symbols you'll encounter and what they mean. Think of this as your visual dictionary.

Power Sources: Fueling the Circuit

- AC Power Source (Single-Phase): A circle with a sine wave inside. This represents an alternating current power supply, common for control circuits or smaller loads.

- AC Power Source (Three-Phase): A circle containing three distinct sine waves. You'll see this powering larger industrial motors and machinery, indicating a three-phase alternating current supply.

- DC Power Source: A long line (positive terminal) and a shorter, thick line (negative terminal) parallel to it. This signifies a direct current supply, often used for electronic controls or specialized DC motors.

- Transformer: Depicted as two or more coils of wire, usually represented by adjacent squiggly lines or rectangles, separated by an air gap or core lines. Transformers are crucial for stepping voltages up or down, providing isolated power for control circuits.

Control Devices: The System's Hands and Eyes

These symbols illustrate how operators or automated processes interact with and influence the circuit.

- Pushbutton (Normally Open - NO): A short, angled line touching a horizontal line, with the angle indicating the pushing action. This contact is open (no current flow) until pressed, closing the circuit. Think of a "Start" button.

- Pushbutton (Normally Closed - NC): Similar to the NO pushbutton, but the angled line crosses the horizontal line, indicating a closed contact that opens when pressed. Essential for "Stop" or "Emergency Stop" functions.

- Limit Switch: Often looks like a pushbutton but includes a roller, lever, or other mechanical actuator component. Limit switches are activated by physical contact with a moving part, signaling position or presence. For instance, detecting if a door is open or a conveyor belt has reached its end.

- Relay Coil: A simple circle with a label (e.g., CR1, M1, K1). This represents the electromagnetic coil of a relay or contactor. When energized, it changes the state of its associated contacts. Pro Tip: Always look for the corresponding contacts elsewhere in the schematic that share the same label; they're controlled by this coil.

- Selector Switch: Often depicted as a switch with multiple positions (e.g., a "run/off/auto" switch). Its symbol usually shows a pivoting line that can connect to different terminals. While not explicitly in the context research's "specific symbols," it's a common control device and good to recognize.

Motor Starters: Bringing the Power

These components are vital for safely and effectively starting, stopping, and protecting motors.

- Contactor: The coil symbol is identical to a relay coil (a circle, often labeled "M" for motor). The contacts, however, are typically larger and designed for high current loads, usually shown as NO contacts that close to supply power to the motor when the coil is energized.

- Overload Relay (OL): Symbolized by heating elements (squiggles or coils) coupled with a normally closed (NC) contact. The heating elements sense excessive current drawn by the motor, and if an overload occurs, the NC contacts open, de-energizing the motor starter coil and shutting down the motor to prevent damage. This is a crucial protective device.

The Workhorses: Motor Symbols

The ultimate destination for much of the power in industrial settings.

- AC Motor (Three-Phase): A circle with the letter "M" inside, with three lines extending from it to represent the three-phase power connections.

- DC Motor: A circle with the letter "M" inside, but only two lines extending, marked with "+" and "-" to denote positive and negative DC connections.

Guardian Angels: Protective Devices

These elements are designed to fail gracefully, protecting more expensive equipment and, most importantly, human lives.

- Fuse: A short, jagged line enclosed within a rectangle or oval. Fuses are single-use devices that melt and open a circuit when current exceeds a safe limit.

- Circuit Breaker: Often depicted similar to a fuse but with an additional line or lever indicating it can be reset. Circuit breakers are reusable protective devices that trip and open a circuit under overcurrent conditions.

- Ground Fault Interrupter (GFI/GFCI): A more specialized symbol indicating a device that detects an imbalance in current flow between the hot and neutral conductors, signaling a ground fault, and rapidly interrupting the circuit. Essential for personnel protection in wet or hazardous environments.

The Arteries: Conductor Symbols

These symbols dictate how electricity flows and how components are connected.

- Wire (Conductor): A simple straight line. This represents the electrical pathway between components.

- Wire Crossing (No Connection): Two lines crossing each other without a dot at the intersection. This signifies that the wires cross paths on the schematic but are not electrically connected.

- Wire Connection: Two lines crossing each other with a distinct dot at the intersection. This explicitly indicates an electrical connection between the two conductors. Without the dot, assume no connection.

Translating Lines into Action: A Step-by-Step Schematic Interpretation

Understanding individual symbols is like knowing individual words. The real power comes from stringing them together to form sentences and paragraphs—interpreting an entire schematic. This systematic approach will help you break down even the most complex diagrams.

- Identify Power Source: Always start here. Locate the AC or DC power sources (or sources, if there are multiple control and power circuits), noting their voltage and phase. This sets the stage for understanding the entire circuit's potential.

- Trace Control Circuit: Once you have the power, follow the path of control power through devices like pushbuttons, selector switches, limit switches, and relay coils. This helps you understand the logic that dictates when things happen. Look for control voltage transformers if the control circuit operates at a different voltage than the main power circuit.

- Identify Motor Starters and Motors: Locate the contactors (their coils in the control circuit, and their main contacts in the power circuit), overload relays, and the motor symbols themselves. This reveals how the control logic ultimately energizes and de-energizes the motor.

- Analyze Interlocks and Safety Features: Don't overlook the protective elements. Identify limit switches that prevent machine movement beyond safe limits, emergency stop pushbuttons, or any other devices designed to prevent hazardous conditions or protect equipment. These are often normally closed (NC) contacts in the control circuit. This is critical for ensuring you're following proper troubleshooting complex motor control circuits safety protocols.

- Follow Circuit Under Different Conditions: This is where the schematic comes alive. Mentally (or physically, with a pencil) simulate the circuit's behavior. What happens when you press the "Start" button? Which contacts close, which open? What if a limit switch is activated? What happens if an overload condition occurs? This mental simulation builds a dynamic understanding of the system.

Case Study: Demystifying a Basic Motor Start/Stop Circuit

Let's apply our knowledge to a classic example: a simple start/stop circuit for a three-phase AC motor, common in many industrial setups.

The Schematic Breakdown:

- Power Source: You'll typically see two distinct power sources.

- Three-phase AC: For the main motor power circuit.

- Single-phase AC (or DC): For the lower-voltage control circuit, often tapped off a control transformer.

- Control Circuit Components:

- Stop Pushbutton (NC): Located at the beginning of the control circuit. It's normally closed, meaning power flows through it to the rest of the circuit. Pressing it opens the circuit, interrupting power.

- Start Pushbutton (NO): Placed after the Stop button. It's normally open, so no power flows through it until pressed. Pressing it closes the circuit.

- Motor Starter Coil (M): Represented by a circle (M). When energized, it pulls in its main power contacts (M) to power the motor and its auxiliary contacts (M1).

- Holding Contact (M1 - NO): An auxiliary contact associated with the motor starter coil (M), connected in parallel with the Start pushbutton. This contact is normally open but closes when the motor starter coil is energized.

- Overload Relay (OL - NC contacts): Located in series with the motor starter coil. These contacts are normally closed, allowing power to the coil. If an overload is detected by the heating elements in the power circuit, these NC contacts will open, de-energizing the coil.

- Power Circuit Components:

- Main Contactor Contacts (M - NO): Three normally open contacts, controlled by the motor starter coil (M). When the coil is energized, these contacts close, supplying three-phase power directly to the motor.

- Overload Relay Heating Elements: These are in series with the main power lines to the motor, sensing the motor's current draw.

- Three-Phase AC Motor: The final component, drawing power when the main contactor contacts (M) are closed.

Operation:

- System Idle: The Stop button is closed, the Start button is open, the motor starter coil (M) is de-energized, its holding contact (M1) is open, and the main contactor contacts (M) are open. The OL contacts are closed.

- Pressing the Start Button:

- When you press the Start pushbutton, it momentarily closes, completing the circuit to the motor starter coil (M).

- Coil (M) energizes.

- Motor Engagement:

- Upon energization, the motor starter coil (M) immediately closes its main power contacts (M) in the power circuit, supplying three-phase power to the AC motor, causing it to start.

- Simultaneously, the coil (M) also closes its auxiliary holding contact (M1) in the control circuit.

- Release Start Button (Seal-in Logic):

- Even when you release the Start pushbutton (which returns to its open state), the circuit to the motor starter coil (M) remains complete through the now-closed holding contact (M1). This is known as "seal-in" or "latching" logic, keeping the motor running.

- Pressing the Stop Button:

- Pressing the Stop pushbutton momentarily opens its NC contact, breaking the circuit to the motor starter coil (M).

- Coil (M) de-energizes.

- This causes both the main power contacts (M) and the holding contact (M1) to return to their normally open states, cutting power to the motor and shutting it down.

- Overload Condition:

- If the motor draws excessive current (e.g., due to a jammed load or a winding fault), the heating elements of the overload relay detect this.

- The OL's NC contacts in the control circuit open, de-energizing the motor starter coil (M), irrespective of the Start/Stop button states.

- The motor shuts down, protecting it from damage. The OL typically has a reset button that must be manually engaged after the fault is cleared.

This example illustrates how a few basic symbols combine to create a functional and protected system, providing a clear path from control input to motor output.

Beyond the Manual: Pro Tips for Schematic Mastery

Becoming truly fluent in motor control symbols goes beyond rote memorization. It requires a nuanced understanding and a strategic approach to schematic reading.

- Context is King: A symbol never exists in isolation. Always consider its placement within the circuit, its connections to other components, and the overall function of the system. A limit switch on a conveyor might mean something different than one on a safety gate. Always remember the broader system, like when you're designing industrial control panels.

- Layered Schematics: Industrial systems often use multiple schematics or layers within a single drawing. You might have a "power schematic" showing heavy-duty wiring and a separate "control schematic" detailing the low-voltage logic. Learn to navigate between these to get the full picture.

- Reading Left to Right, Top to Bottom: In most Western schematics, power generally flows from left to right, and logic generally flows from top to bottom. This convention provides a natural flow for interpretation.

- Component Tags and Cross-Referencing: Pay close attention to labels like "CR1," "M2," "OL3." These tags connect coils to their associated contacts or refer to components on different pages of a multi-page schematic. Mastering cross-referencing is crucial for complex systems.

- The "What If" Game: Before you troubleshoot a live circuit, play the "what if" game with the schematic. "What if this limit switch fails closed?" "What if that relay coil loses power?" Mentally simulating different scenarios helps you anticipate problems and pinpoint potential causes.

- Variations and Vendor-Specifics: While standards exist, don't be surprised to encounter slight variations in symbols depending on the age of the schematic, the industry, or even the specific manufacturer. Develop an eye for these differences and always refer to the legend or symbol list if provided.

- Common Pitfalls to Avoid:

- Assuming a connection without a dot: Always look for the explicit connection dot. No dot usually means no connection, even if lines cross.

- Ignoring safety interlocks: These are often NC contacts that, if bypassed or miswired, can create dangerous conditions.

- Not understanding NO/NC states: This is fundamental. A misplaced NO where an NC should be, or vice versa, will completely change the circuit's behavior.

Your Toolkit for Continued Learning

Mastering motor control symbols is an ongoing journey. The more you immerse yourself, the more intuitive it becomes.

- Online Databases and Textbooks: Numerous resources are available. Look for guides specifically tailored to industrial controls and the NEC.

- Formal Training Courses: Many vocational schools and industrial training centers offer specialized courses in motor controls, schematics, and industrial automation.

- Manufacturer Manuals: Equipment manufacturers provide detailed schematics and symbol legends in their documentation. These are invaluable for understanding specific machinery.

- Hands-On Practice: The best way to learn is to do. Grab any schematic you can get your hands on—from an old machine, a textbook, or online—and start tracing circuits. Mentally simulate operation, identify components, and predict behavior.

- Explore Related Fields: Modern motor control systems are often integrated with Programmable Logic Controllers (PLCs). Understanding the basics of PLC programming will give you a comprehensive view of how control logic is implemented digitally.

For a deeper dive into the broader world of electrical blueprints, consider exploring a complete electrical symbols diagram to expand your visual vocabulary even further.

Empower Your Expertise: The Final Word

The world of industrial automation demands precision, speed, and safety. Your ability to quickly and accurately interpret common power and motor control system symbols is a cornerstone of meeting these demands. It empowers you to tackle complex troubleshooting with confidence, ensure every wire is placed correctly, and contribute to a safer, more efficient workplace.

Don't just read about these symbols; engage with them. Print out a schematic, grab a highlighter, and trace those lines. Understand the story each symbol tells and how they combine to create the intricate ballet of industrial machinery. Your fluency in this silent language will not only elevate your expertise but also cement your reputation as the go-to professional on the shop floor.